Oil analysis . . . condition monitoring . . . reliability solutions – these are not static concepts or services; rather, they evolve constantly over time to meet the ever-changing maintenance needs of industry as machinery and components are updated and redesigned.

Condition monitoring specialist company WearCheck, based in South Africa and around the African continent, is dedicated to remaining at the forefront of the reliability solutions game, and invest regularly in new laboratory equipment and training for their scientists.

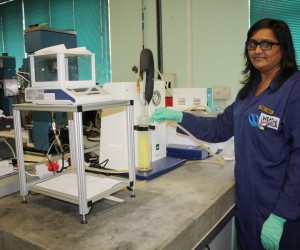

The latest addition to WearCheck’s Pinetown laboratory is a brand new air release tester – a sophisticated instrument that measures the ability of an oil to release entrained air by pumping air through the oil sample at predetermined conditions.

Laboratory manager Meshach Govender explains, ‘We record the time taken for the entrained air in the sample to reduce in volume to 0.2%. Entrained air that is not readily released from the oil can lead to spongy hydraulic action, inability to maintain oil pressure, incomplete oil films and the acceleration of oxidation of the oil.

‘The new air release service was previously outsourced, and is now done in-house. This has reduced the turnaround time for sample results, and is of particular benefit to our customers with turbines and hydraulics, as well as gear oils to a lesser extent.’ [*please see “Further technical information” below for an outline of the air release process.]

WearCheck offers a host of tests, including the scientific analysis of used oil, which form a complete condition monitoring programme, servicing components in many industries, predominantly mining, electrical, earth moving, aircraft and transport.

This year, WearCheck celebrates their 40th anniversary of condition monitoring excellence.